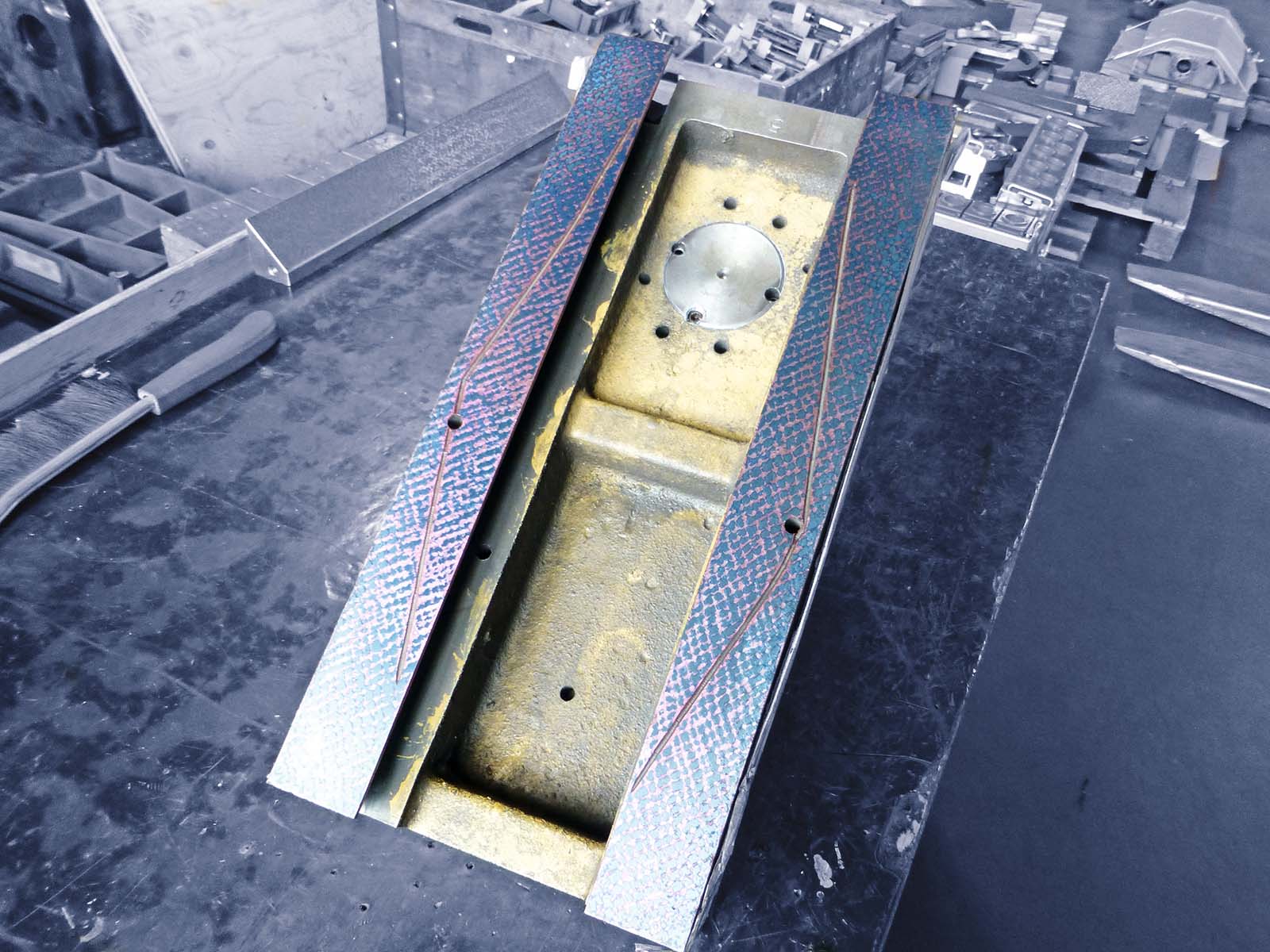

Bushings

Like guides, slide bushings can lose their dimensional accuracy. Ignoring this may result in considerable damage – in the worst case even the total failure of a machine. New bushings can be made to prevent this from happening. These are then scraped in on-site, making everything angular and dimensionally true again. We have extensive experience in the replacement of bushings and can therefore ensure that your machine has a long service life.

Hatebur machines

Thanks to over 30 years working together with Hatebur, we have developed into specialists for their products. If a Hatebur press requires scraping, assembly or on-site machining, LUMAG AG is the right partner for you.

We have already scraped a variety of new machines for customers. We are also the first port of call for overhauls that require scraping.

Machine geometry

If lathes, milling, drilling or grinding machines are no longer achieving the desired accuracy, it is time for an overhaul. As a result, scraping the guideways is often recommended. We will make your guides free of any play once more or correct any indentations that have formed over time.

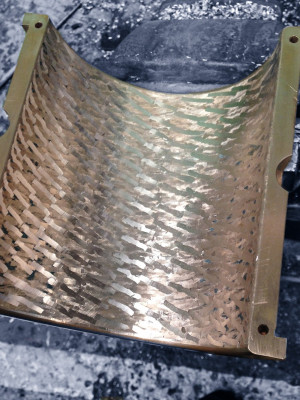

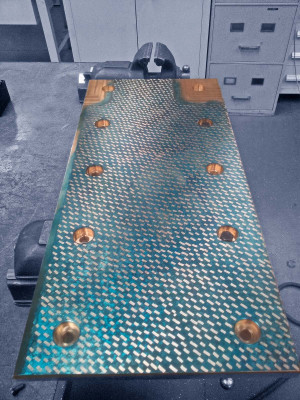

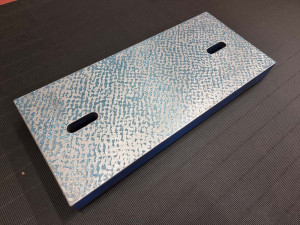

Straight edges / touching plates / oil pockets

If you are working with touching material, you should check it regularly and, if necessary, re-scrape it. Otherwise, there is a risk that faults will be passed on to the tool you are manufacturing.

In our workshop in Roggliswil, we can scrape or inspect panels up to 1,200 x 800 mm.

Do you need an oil pocket in a guide? We would be happy to machine these in for you.