Drilling

there, on-site.

In the event of a defect, the thread can be restored to its original size by drilling it out and using a threaded insert.

In the case of a cracked machine frame, we can help by using a tie rod to draw it together. If required, we can offer you a custom solution – tailored to meet your force and load measurements.

We can take on this drilling work for you, right there on-site

- Setting new holes

- Stripping out the threads

- Using tie rods

- Calculating force and load

Lathing and spindle work

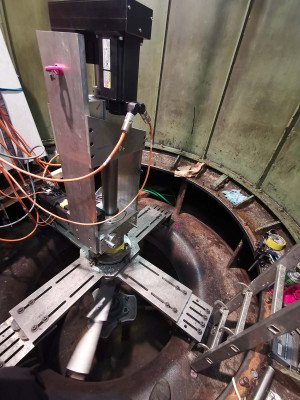

Are your drilled holes worn out, or has a shaft shrunk? We can come by with our machining units and fix the problem.

Using our mobile equipment, we can drill-finish holes from 40 mm to 1.8 m – so that they are then as clean as before – or turn them to form an H7 fit if needed. If you need to get back to the original dimension, we can also weld and skim the hole, for example in the case of an excavator arm.

With shafts, the original dimensions can be regained by metal spraying or welding. If this is not required, one option is to lathe it until the desired dimension is reached.

We carry out the following lathing and spindle work on a mobile basis

- Spindling out holes

- Welding holes

- Lathing shafts / spraying metal / welding

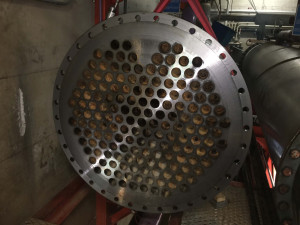

Flange turning

Do you have a worn-out joint that is now leaking? Our flange turning device can help. We can come over and turn the surface flat and at an angle. So that everything is tight again.

Milling operations

We can carry out all this work on-site, using our milling equipment that can be set-up on a modular basis.

For example, have you lined up a modification on a machine, and must changes be made to the machine frame to achieve this? Or is a surface heavily worn, and needs to be milled clean again? We are happy to help.

If you need a complicated geometric shape to insert a new part; or if you want to circular mill a large thread, we can help with our CNC-controlled machines.

We carry out this milling work at your premises.

- Milling surfaces

- Milling contours

- CNC milling

Work on Hatebur equipment

We have tailor-made machines for working on your Hatebur equipment. This allows us to carry out all kinds of machining. This includes:

- Milling the contact surface on all systems with integrated lateral transport.

- Re-milling the press slide surface, whether installed or removed, on AMP-50/70 HM 35/75.

- Repositioning the press wedges, whether installed or removed, on AMP50/70.

- Re-spindling holes for all systems.

- Re-milling the contact and support surface on AMP20/30 in a design with integrated transverse transport.

- Only re-milling the contact surface on AMP20/30. Only the pressure plate and the tool stand need to be removed to do this.

Honing

In this process, metal surfaces are accurately machined with the help of appropriate tools or machinery and smoothed to achieve high dimensional accuracy when drilling. This process is primarily known from engine construction, where cylinder bores are honed, creating the distinctive cross pattern.

We can also hone an existing machine on-site. This is to make a hole have the right dimensions or make two connecting holes of the same diameter and in alignment.

Metal spraying

Do you have a worn-out shaft? With metal spraying, we can help you to, for example, bring a bearing seat back to its original dimensions.

During the spraying process, we apply a layer of metal that is then treated by our machining units. This allows the original bearing seat to be restored.